Sheet metal is an important and widely used material in modern manufacturing. It is used in household appliances, cookware, automobiles, electrical equipment, and more complex mechanical parts.The process of manufacturing these parts, components, and assemblies using sheet metal is called sheet metal fabrication.

Material selection is a crucial step in sheet metal forming, directly impacting the manufacturability, functionality, and lifespan of the product. Material selection requires comprehensive consideration of the actual application scenario, mechanical requirements, and environmental conditions. This process includes a series of techniques or methods such as cutting, forming, joining, assembling, and finishing to ultimately produce the desired parts. The following introduces several commonly used sheet metal materials, their characteristics, and main applications:

**Stainless Steel**

High strength, good corrosion resistance, and excellent ductility; commonly used in medical devices, food processing equipment, kitchenware, and building components. Grades 304 and 316 are widely used due to their excellent chemical corrosion resistance.

**Aluminum**

Lightweight, high strength-to-weight ratio, and corrosion resistant; suitable for outdoor facilities, shipbuilding, and complex shape designs.

**Hot-Rolled Steel**

Lower cost, flexible, and easy to process; widely used in construction, automotive frames, and railway tracks. Its surface is relatively rough, and dimensional accuracy is generally lower than cold-rolled steel.

**Cold-Rolled Steel**

Higher strength than hot-rolled steel, with superior surface quality and dimensional accuracy; commonly used in structural parts, household appliances, and aerospace components.

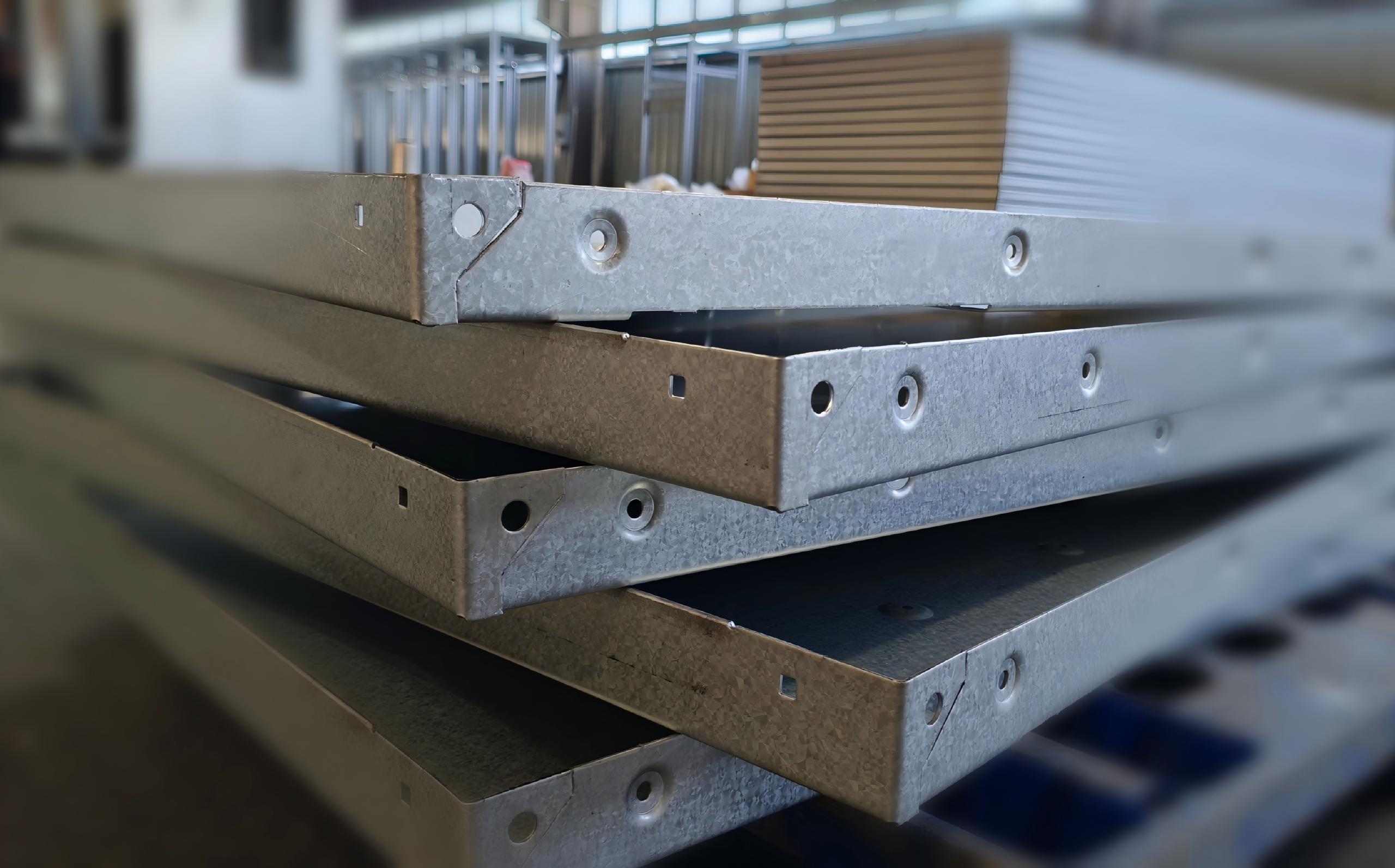

**Galvanized Steel** Galvanized steel offers enhanced corrosion resistance and is widely used in roofing, HVAC systems, refrigeration equipment, and agricultural machinery, combining durability and economy.

**Copper**

Excellent electrical and thermal conductivity, along with antibacterial properties, it is primarily used in electrical wires, busbars, heat exchangers, and medical equipment. Its alloy brass (copper-zinc alloy) improves machinability and appearance.

**High-Strength Low-Alloy Steel (HSLA)**

Stronger and lighter than ordinary carbon steel, it is widely used in automotive manufacturing, bridge engineering, cranes, and heavy machinery, helping to reduce weight and improve fuel efficiency.

Material: Galvanized steel, weathering steel, stainless steel. Customization available.

Thickness: 0.5mm - 3mm, customizable.

Size: customizable.

Logo: customizable.