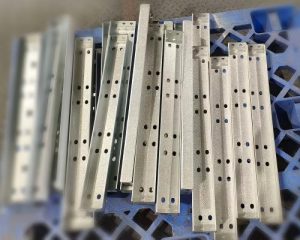

Sheet metal manufacturing refers to the process of creating metal casings using a variety of techniques. The term is broad, encompassing cutting, punching, bending, welding, assembly, powder coating, and other related metalworking methods.

Sheet metal enclosures offer significant advantages in manufacturing, such as shorter production cycles and relatively lower costs. With proper design, these enclosures can achieve optimization in both function and appearance. Henan Heshan Electric Co., Ltd. possesses expertise in cutting, bending, and surface treatment, enabling it to provide customers with ideal sheet metal enclosure design and manufacturing support.

We offer a variety of surface treatment processes to choose from:

Powder coating

involves electrostatically applying powder coating to the surface of a workpiece, followed by high-temperature curing to form a coating. This process offers superior mechanical strength, adhesion, corrosion resistance, and aging resistance compared to traditional spray painting, but it is also more expensive.

Anodizing

An electrochemical surface treatment process primarily used for aluminum materials can improve surface hardness and significantly enhance corrosion resistance. The anodic oxide layer bonds firmly to the substrate and is not easily peeled off during daily use.

plating

This process, based on the principle of electrolysis, deposits a metal layer on the surface of a conductive material. It is suitable for metals and specially treated plastics. Common types include chrome plating, zinc plating, copper plating, and nickel plating, primarily used for oxidation prevention and decorative purposes.

Digital printing and screen printing

Two post-printing finishing techniques enhance the professional look of the product, clearly marking connectors, switches, ports, and other markings on the casing and parts. They are also suitable for printing company logos or artistic designs.

Material: Galvanized steel, weathering steel, stainless steel. Customization available.

Thickness: 0.5mm - 5mm, customizable.

Size: customizable.

Logo: customizable.